RECENT PROJECTS

Lean in a Make-To-Order Job Shop Environment

In 2008, CMA began working with a small company in the Mid-Atlantic region that was a make-to-order stone (e.g. granite, marble, glass) fabricator. As with all “job shops” there was great variation from order to order. Orders could vary from a single countertop, to an entire kitchen, to the complete interior and exterior of a commercial bank. Adding to the challenge was the incredible amount of competition in the industry resulting in tremendous price and service (i.e. lead time) sensitivity.

An enterprise value stream map was created for the business. It became apparent that inconsistent customer service and lengthy lead times through the pre-production and production processes were hindering the company’s ability to garner new business. Excessive costs due in part to the inability to handle demand variability in production (e.g. labor management) as well as quality issues (e.g. scrap, rework) were further harming its competitiveness. The company had attempted to implement an Enterprise Resource Planning (ERP) system to provide much needed planning capability and to improve organization of operations in general. By the time of the VSM event, it was widely agreed that the 3-year ERP effort was a failure. Instead, the company chose to pursue the Lean Enterprise path. Its emphasis on “simple and visual” struck a chord with an exasperated owner.

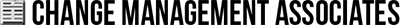

As with many lean transformations, the effort began with education of the workforce, and a simple clean-up of the facility as “5S” was initiated. In addition, a study was conducted to determine an appropriate measure of demand – a “takt time” for the business. This is often a difficult task in a job shop environment. “Linear feet of treated edge” was determined to be appropriate because it directly correlated to the amount of labor hours required to “finish” the order. Finishing was the real constraint of the production system. Only on occasions would the various “upstream” equipment related processes become constrained. This could be handled as the need arose. It was agreed that it would be Finishing that would drive the entire system. A simple spreadsheet based tool was created to monitor demand versus capacity making use of information available from the quote when an order was received. This information was also used to “level load” production via a “fixed” schedule.

Flexibility in production was created by an extensive cross-training effort making use of standard work and “Job Instruction (JI)” techniques. The flow of materials and orders was controlled by the application of a “pull” system. The pull system did not allow for orders to accumulate on the shop floor as had happened in the past. Therefore, much desired workplace organization could be maintained at all times – during busy periods, as well as slow times. The pull system also triggered re-allocation of resources to other processes when necessary. A set number of carts were used in the pull system as well as a series of “first-in-first-out” (FIFO) lanes.

Within one year, the result was a very predictable system that could provide a consistent two week lead time to the customer, including the pre-production process. On time Delivery was improved from 85% to 98%. Productivity improvement of approximately 20% was realized and quality costs reduced by 50%. The focus in 2010 is to reduce overall lead time to one week which will require a re-design of the pre-production process in addition to further enhancements to the production system. Total Productive Maintenance (TPM) will also be an important initiative in the coming year.

Lean Transformation in a Design-to-Order Company

In 2009, Change Management Associates began working with a design-to-order company in the video and audio disk business. The company provided a full range of services to its customers. It could create graphics for the CD or DVD, its packaging and promotional materials, or it could make use of customer supplied graphics. Customers could request custom packaging or make use of existing designs. All orders went through a “pre-press” process to prepare for the various printing and bindery operations that would be necessary to process the order. Of course, all orders went through one of several replication or duplication processes to produce the requisite number of disks. The company even offered “engineering” services to help develop the content of the disk. This “one-stop” shopping created great challenges to operations and the business system as a whole.

An Enterprise Value Stream Map was created for the “Quote-to-Cash” process, taking into account the varying nature of orders. The current state displayed numerous hand-offs through the pre-production process as each order accumulated an estimated 5,000+ feet in distance traveled. In production, the issue was “getting the right item in the right quantity at the right time” to the Packaging Department so that it could complete the order. “On-Time-Delivery to Packaging” was estimated to be approximately 70%. Also the amount of work-in-process (WIP) in the production system at any time displayed wild variation. This undermined workplace organization, and created much non-value added activity handling, re-handling, searching and the like.

The company addressed the pre-production flow by implementing flow concepts in the office. Initially a single cross-functional team or “cell” was piloted to prove the concept. Cross training was required as what had previously gone through seven departments would be consolidated into four roles. Then the roles were co-located and assigned to particular Inside Sales associates. This approach would allow for the more effective communication of often ambiguous information common in such creative processes. The results of the first team measured after several months was a 50% reduction in lead time, and an estimated 25% productivity improvement when it was compared to the historic departmental silo approach. The “Project Manager” role was able to handle 50% more orders or “projects” at any time. A second team was initiated with some modification as the pilot continues. Ultimately a total of 9 to 10 such teams will be needed to match demand.

In production, the clear need was for a Pull System. After all, the objective of pull is to have “the right item in the right place in the right quantity at the right time”. Several sequential pull lanes were carefully located throughout the disk operation leading up to Packaging. Each was sized according to demand and desired throughput time. Carts would be used to execute the pull system. Adherence to a set schedule was also established. The pull system provided much needed stability and predictability to the system. WIP no longer varied wildly. Packaging received much better service from its internal suppliers as On Time Delivery improved to 85% and climbing.

Based on this experience, the company will be implementing a similar system throughout the printing and bindery operation leading up to Packaging in 2010. Several issues with the “batching” of orders in the pre-press operations also had to be addressed. Previously orders were batched to maximize material usage but this practice created problems when orders required over several days were batched together. Several “experiments” were run. The conclusion was that batching within the same day would not increase waste in any significant way. A further enhancement expected in 2010 will be to add sequencing rules that will further synchronize the various “paths” to Packaging, and allow for an additional reduction in WIP while further improving service.

Lean Product Development

In 2009, Change Management Associates began working with an existing customer on its product development process. The company is in the highly competitive furniture industry. As with most companies, they struggled with time to market, the ability to deliver more designs to market, and accountability for design quality after product launch. Particularly challenging in this industry is the importance of often difficult to describe esthetics, styles, themes and the like. Development cycles could take as long as 30 months for projects. Due to lengthy development times, anticipating market acceptance was hit or miss.

The existing development system was mapped using the powerful Value Stream Mapping tool. During the event key interruptions to the flow of development projects were identified. In addition, the typical difficulties with conveying complete and accurate information throughout the development process were apparent. Lack of clear roles and responsibilities and a general lack of accountability plagued the existing system.

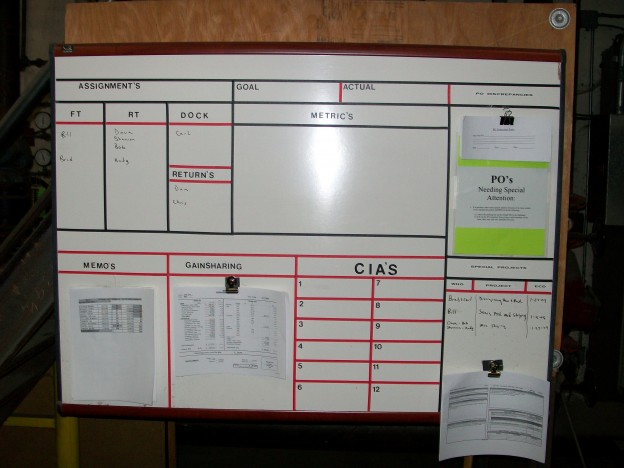

The organization saw the need to implement effective project management techniques to its development process, well beyond what was historically done at the company. In the past project plans were developed, milestones identified, periodic reviews performed, but performance problems persisted. Something more was needed. Simple and visual project management techniques were implemented. Visual “storyboards” were created to manage each development project. Voice of the customer information was communicated during a cross-functional kick-off meeting which assured that often unclear design objectives were more effectively understood by all team members. This information was visually displayed on the storyboard for ongoing reference during the life of the project. In the past this information was shared with a limited number of people who were expected to disseminate it to others.

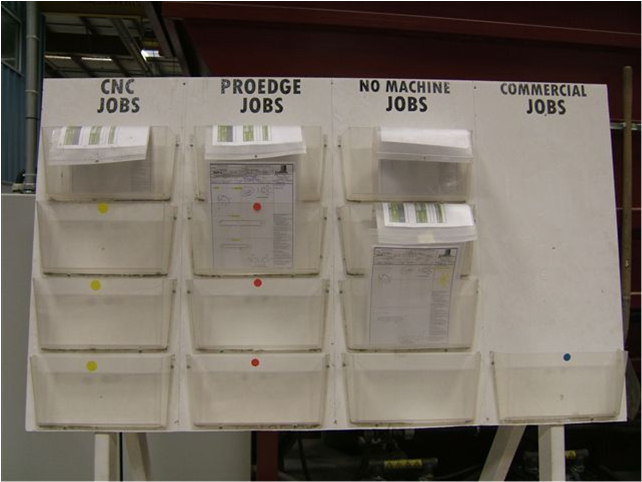

Clear roles were defined for the project teams, along with standard work for each. Project timelines were created as before but were reviewed more frequently, thereby providing a “cadence” to each project. The teams would meet during weekly “stand-up” meetings, where in the past they met once a month which was deemed reasonable given the fact that projects took place over a 18 to 30 month period. Clear expectations were defined for key activities due in the coming months, and accountability improved as a result. A simple, visual tool was developed to monitor the progress of all projects in process. This tool could also be used to identify capacity constraints in the development process. Previously, no such visibility existed.

New technical capability allowed for quick turn around of product renderings decreasing 1 – 3 months off the back-end of the development process. This also provided the ability to quickly process changes late in the development process, if necessary. Apart from this technological capability, all other changes involved the lean basics of standard work and visual management.

While still early in the implementation process, changes made to date are providing a more predictable development system. Not without some difficulties, most all development projects are now on schedule, and documentation and quality has improved. A consistent 12 month cycle is now possible for one type of projects and 18 months for another. This represents an approximate 35-40% reduction in development lead time. The development of more products is now possible as capacity has been freed up. Approximately 25% more active projects are being worked on by design teams, and there has been a decrease in rework on initial specifications.

- Rendering of Project “Storyboard”

- Rendering of Visual Management Board for Multiple Projects

Lean Leadership Development:

In 2008, Change Management Associates worked with a manufacturer and distributor of formulated and packaged petroleum products. The company had been practicing lean for about eight years. The owner felt that they had “lost their way”. An on-site assessment confirmed this fact. The 5S program became simply a housekeeping effort (part of the 3rd S), and not a very effective one at that. Pull systems that were implemented in the past were not improved over time. Quick Changeover concepts were not maintained. Some elements of the lean system were missing altogether. There was a steady decline in the Continuous Improvement culture that was previously prevalent. A root cause of this “backslide” was the lack of ongoing leadership development. New supervisors and managers were hired over time, and key role changes of existing managers took place. The lack of some means of ongoing leadership development is a common cause for an organization’s inability to sustain and build on the gains made during a lean implementation.

A 40-hour development program was delivered to all supervisors and managers over several months. The first part of the program covered the requisite skills of a leader in a lean enterprise including: Organizing and Planning, Communication, Developing Trust, Motivation, Observation and Providing Direction. Foundation “tools” such as Job Instruction (JI) and Job Relations (JR) were reviewed and the participants given the opportunity to apply them. Gemba walks, true 5S audits and other “observation” related activities were conducted to develop these skills. Participants developed their own “standard work” for their particular roles, as part of a “Lean Daily Management System (LDMS)”. The LDMS included Visual Management techniques to help sustain practices over time. The second part of the program covered “Plan-Do-Check-Act (PDCA)” and the basic quality management tools which were not previously put in practice with any consistency. Projects were identified to assure application of the tools. Processes were put in place to identify and select opportunities for improvement over time.

Importantly, the organization developed the internal resources who would deliver training to all new people hired into leadership roles, as well as to assure continual development of existing leaders over time. The company licensed training materials from CMA for this purpose. This would provide the organization with the means to sustain in the future.

Lean Office Train-the-Trainer Program

In 2009, CMA began working with a global manufacturer of power conditioning devices to develop internal Lean and Continuous Improvement capability specifically focused on business processes. The company went through CMA’s Lean Office “train-the-trainer” program. The program consists of two modules: Value Stream Mapping, and Office Kaizen. The VSM module develops the understanding and skills of a select group of individuals to facilitate events using the value stream mapping technique – the assessment and planning tool of lean practitioners. The Office Kaizen module develops similar abilities to facilitate office kaizen events – highly focused rapid improvement events. It is during kaizen events that the changes envisioned in the future state value stream maps are actually made in the workplace.

The internal individuals expected to serve as future facilitators would learn the concepts and develop the requisite skills through actual application of the tools and techniques. Only by this manner, can the learning be effective. Participants went through three “cycles of learning” for each module – six weeks in total. Three Value Stream Mapping events were conducted as well as three Office Kaizens. This would allow the company to realize near immediate return on the investment to develop their internal capability on the road to self-dependency.

Areas that the company chose to address during the program included the “Order-to-Cash” process, the annual management budgeting process, and Order Fulfillment. The company realized approximately $3,000,000 in bottom line savings during the program, plus another $500,000 in cost avoidance for the planned purchase of new software that was deemed unnecessary. This represented an approximate 28x return on investment. Other benefits were a reduction in lead time for the budgeting process from 165 days to 20 days (-88%), and Order Fulfillment lead time was reduced by 45%. The lead time to update Price Lists was reduced by 83% which had previously caused customer dissatisfaction and much related non-value-adding activity. In fact the process time associated with this activity was reduced from 100 hours per week to 20 hours (80%).

Based on the success of the Lean Office train-the-trainer program, the company chose to repeat a similar program in each of their main manufacturing operations beginning in 2010.

Lean Healthcare

Through an affiliate, CMA worked with a mid-west hospital to apply lean throughout its operations. Starting in the Emergency Room/Department, value stream maps were created, and a future state created that would improve performance and service to patients. Included was: a form of pull system, near real time awareness of “takt image”, standard work, 5S, and other lean concepts. Methods were implemented to monitor patient lead time upon entering the ER to the time he or she was seen by a physician. Visual methods were used to identify patient lead time that exceeded established “service levels”. This triggered a pull system to better insure that service levels would be maintained. Workplace organization by application of 5S techniques were implemented, including standardization of the examination rooms. Fundamental changes in the process sequence by which patients were signed-in, a preliminary examination performed, triaged and so forth were made to improve flow and the quality of care. Many of the changes were made as part of a series of kaizen events – focused rapid improvement events involving cross-functional teams of people during a set period of time.

One kaizen event focused on the information flow, specifically the update and filing of patient charts. Historically, information was often lacking from the charts. Associates responsible for documentation processing and billing would discover the problem when the chart was returned to the office. Much non-value-added activity ensued to try to track down the responsible parties to provide the missing information. This could take several days as charts were often turned in at the end of a shift, and the problems discovered after people had left for the day or for days. Numerous attempts to follow up would be made over the subsequent day or days. A more proactive approach was implemented. Documentation processing personnel would walk through ER and go to designated drop-off points to collect charts and related information. This occurred at a regular frequency (every 2 hours). Problems were discovered in more timely manners, and were more easily resolved as a result. This simple system made use of specially designed moveable carts that included everything from a laptop computer to label makers, even a trash can – everything to process the documentation “on the move”. A prototype was created during the three day kaizen event, and piloted. Based on the pilot, modest revisions were made, and additional carts fabricated.

Clearly many of the lean concepts traditionally found in manufacturing can be applied to healthcare operations. It just requires a little creativity, and a willingness to try. CMA has worked with numerous healthcare organizations since the early 1990s to apply operational excellence concepts to improve performance, increase patient satisfaction, and improve the quality of care.